There are many feedthrough parameters that can be modified or custom

designed to ensure that the final product matches your application.

These include the mounting configuration, the ferrofluid used, bearing

type and position, the shaft strength and termination features,

the residual magnetic field and the location of sealing stages (on

the stator or rotor). These pages include examples of custom engineered

feedthroughs and sealing sub-systems designed and built by Ferrofluidics

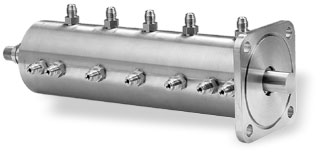

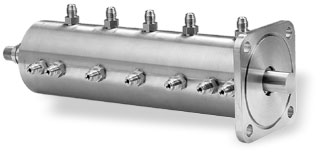

Rotary gas union

|

|

Applications: CVD, vacuum deposition

systems, gas handling modules

Ferrofluidic rotary gas unions offer manufacturers

of CVD and other deposition systems an efficient and flexible

method of introducing gases into a process. A static gas feed

runs into the rotating shaft which supports the wafer. This

ensures that the gas outlet is in the center of the wafer,

resulting in uniform coating characteristics.

|

Multi-axial Feedthroughs

|

|

Applications: wafer handling, CVD wafer

rotation with stationery inner shaft

Ferrofluidics offers multi-axial

feedthroughs for wafer handling applications. These offer

extremely high repeatability with zero backlash. Linear motion

can be incorporated and a cantilevered seal design is optional

for UHV optimization. Since the feedthroughs employ a single

shaft per axis to transmit torque to the load, torsional stiffness

is maximized allowing for the highest torque transmission

of any UHV wafer handling rotary sealing technology.

|

Reactive gas seal

|

|

Applications: MOCVD, LPCVD, PECVD, designs

where aggressive cleaning agents are used

Reactive gas seals for applications such

as MOCVD use an inert fluorocarbon based fluid. They feature

a cantilevered seal design to protect the bearings from process

gases. Special materials are used in the seal construction.

Inert gas purges or protective plating can also be added to

prevent corrosive attack of seal components.

|

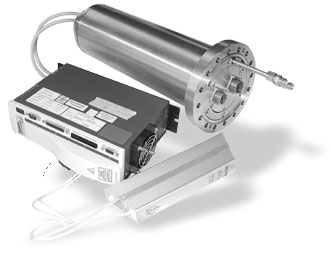

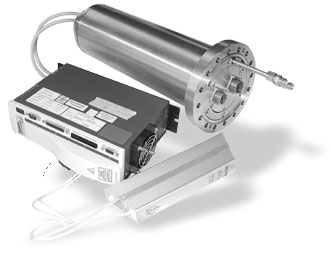

In-line drive motorized feedthroughs

|

|

Applications: anywhere where a motor

is used, particularly where servo control is necessary

An in-line motorized feedthrough

is compact in comparison to an offset or shaft-coupled drive.

Ferrofluidic in-line motorized feedthroughs feature a brushless

servomotor and matching amplifier with power supply and sinusoidal

commutation. Application appropriate feedback devices and

command loops are incorporated. As the feedthrough has the

motor fully integrated around the shaft rather than coupled

to it, it provides optimum drive-to-load torque efficiency

over the life of the product. Direct drive feedthroughs are

available with either solid or hollow shafts.

|

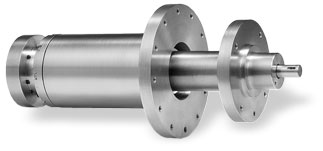

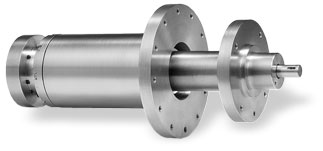

High speed, large diameter hollow shaft feedthroughs

|

|

Applications: optical coating applications, 300 mm

wafer rotation mechanisms

High speed, large diameter hollow shaft feedthroughs

are ideal for optical coating applications, e.g. fiber optic

filter manufacturing. These feedthroughs are configured with

a double Ferrofluidic seal to enable static access to the

rear of the seal. Drive is supplied via a toothed belt through

the side of the housing or an integral brushless motor within

the feedthrough housing. The product can then be accurately

observed or measured through the large diameter hollow shaft

without the difficulties associated with a rotating window.

Seals with an 8" internal diameter can be used at speeds

up to 1,000 rpm.

|

High precision spindle design

|

|

Applications: wafer handling, ion implantation

Ferrofluidic spindles can be engineered to

rotate with as little as 0.0001" (0.005 mm) of run-out.

These products are ideal for high precision wafer handling/aligning

applications and wafer/substrate rotation applications where

wobble requirements are very stringent. Axial, radial and

torsional spindle stiffness is achieved by custom engineering

the bearing and shaft designs.

|

Compact designs

|

|

Applications: FLIR devices, retrofit feedthroughs, rinser-dryers

Ferrofluidics offers extremely compact seals

with small seal envelopes. These are sometimes the only option

in the case of retrofits where there is limited axial or radial

space available. In new designs they are often beneficial

to the overall system layout.

|

Rotary-linear feedthroughs

|

|

Applications: wafer handling and alignment with Z-motion

Rotary linear feedthroughs integrate a Ferrofluidic

rotary seal with an edge-welded metal bellows linear seal.

They use pre-loaded angular contact rotary bearings and sleeve

or ball-type linear bearings. Such feedthroughs are ideal

for wafer handling and aligning applications where indexing

and translation are involved.

|

Retrofit feedthroughs

|

|

Ferrofluidics offers a range of retrofit feedthroughs

for many vacuum systems supplied by leading semiconductor OEMs.

Please call for details about the feedthroughs available for

your system. |