|

Audio Fluids

Audio Fluids

Audio Ferrofluids

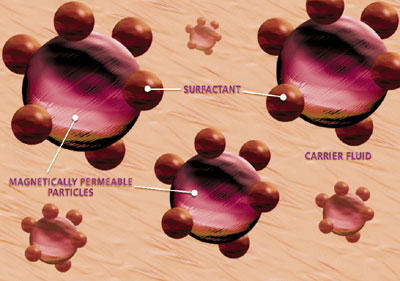

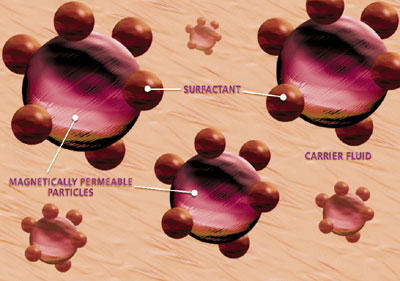

A ferrofluid is a stable colloidal suspension of sub-domain magnetic

particles in a liquid carrier. The particles, which have an average

size of about 100Å (10 nm), are coated with a stabilizing

dispersing agent (surfactant) which prevents particle agglomeration

even when a strong magnetic field gradient is applied to the ferrofluid.

In the absence of a magnetic field, the magnetic moments of the

particles are randomly distributed and the fluid has no net magnetization.

|

When a magnetic field is applied to a ferrofluid,

the magnetic moments of the particles orient along the field

lines almost instantly. The magnetization of the ferrofluid

responds immediately to the changes in the applied magnetic

field and when the applied field is removed, the moments randomize

quickly.

|

|

In a gradient field the whole fluid responds

as a homogeneous magnetic liquid which moves to the region

of highest flux. This means that ferro-fluids can be precisely

positioned and controlled by an external magnetic field. The

forces holding the magnetic fluid in place are proportional

to the gradient of the external field and the magnetization

value of the fluid. This means that the retention force of

a ferrofluid in a gap can be adjusted by changing either the

magnetization of the fluid or the magnetic field in the gap.

Audio ferrofluids are based on two classes

of carrier liquid: synthetic hydrocarbons and esters. Both

oils possess very low volatility and high thermal stability.

The choice of fluid is dictated by the environmental considerations

of the application (e.g. humidity, adhesives, contact with

water, solvent vapors and reactive gases) combined with the

best balance of magnetization and viscosity values to optimize

the acoustical performance.

|

By varying the quantity of magnetic material in

a ferrofluid, and by using different carrier liquids, it can be

tailored to meet a variety of needs. The saturation magnetization

(the maximum value of the magnetic moment per unit volume when all

the domains are aligned) is determined by the nature of the suspended

magnetic material and by the volumetric loading of the material.

The physical and chemical properties such as density and viscosity

correspond closely to those of the carrier liquid.

| Ferrofluidics' highly

refined manufacturing process, combined with a long term quality

assurance program is the key to its repeatable, reproducible

product quality. |

Ferrofluid | Vacuum

Feedthroughs | Thermoelectric Modules

Contract Manufacturing | Literature

Rack | Specialty Seals

Inertia Dampers | Electron

Beam Evaporation

|