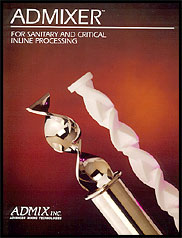

Admixer™ - For Sanitary Static Mixing & Blending

The concept behind a static mixer is simple: fluid flowing through a pipe is channeled through a geometric arrangement of mixing elements. The element geometry within the housing causes the flow to divide, mix, divide again and mix again until complete. The flow then continues in a pipe as if it had gone through conventional batch mixing in tanks, with the distinct difference that the degree of homogeneity can be precisely controlled within the sanitary static blender.

The concept behind a static mixer is simple: fluid flowing through a pipe is channeled through a geometric arrangement of mixing elements. The element geometry within the housing causes the flow to divide, mix, divide again and mix again until complete. The flow then continues in a pipe as if it had gone through conventional batch mixing in tanks, with the distinct difference that the degree of homogeneity can be precisely controlled within the sanitary static blender.

-

Highly predictable mixing and dispersion

-

100% product uniformity and distribution from controlled shear and turbulence

-

Meets 3A TPV Standard #35-03

-

Meets USDA-Dairy Requirements

-

Low capital cost & maintenance

-

Improves safety and sanitation of mixing operation

-

50-90% less power consumption than mechanical mixers

-

Total mechanical reliability - no moving parts, no electrical requirements, easy installation

-

Superior corrosion or abrasion resistance

-

Excellent process versatility - capable of handling viscosities over 1 million cps