VacuShear® - Sanitary Vacuum Liqui-Processor

How The VacuShear Vacuum Liqui-Processor Works

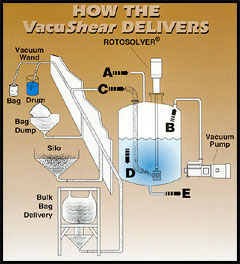

A. Liquid materials are introduced into the mix tank to a level of 1/2 to full batch height. The Rotosolver is turned on from the mixer control panel.

B. The vacuum pump is engaged whereby vacuum builds in the tank, providing positive suction at the in-tank delivery tube.

C. Dry powders, solids, semi-solids or liquids are introduced via the vacuum delivery system directly from bags, drums, bag dump stations or loss-in-weight feeders. A unique benefit is the ability to store and convey all materials from a remote, dry area and avoid messy clean-ups of typical powder additions. Powder feed rates up to 400 lbs/min will automatically occur as vacuum is maintained.

D. All dry materials are introduced below the liquid level immediately at the mixing head. Constant vacuum eliminates aeration, foaming and dusting commonly generated by conventional processors.

E. Once charging is complete and isolation valves are closed, the Rotosolver can be shut off or slowed down, while vacuum is maintained to allow complete deaeration and de-foaming to occur. When all parameters are satisfied, the tank can be unloaded under atmospheric conditions.