Boston Shearmill®

High Intensity Wet Milling, Homogenizing & Particle Reduction

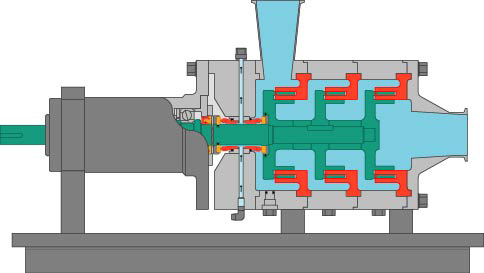

How The Boston Shearmill/Shearpumps Homogenizer Works

The Boston Shearmills/Shearpumps are capable of processing very high throughputs at extreme shear rates producing an average mean droplet size of .05-3 microns.

Shear heads of the Shearmill/Shearpump are comprised of a multi-slot rotor turning at high speeds in close proximity to a multi-port stator. Each shear head of the homogenizer has a double ring design providing two stages of mixing at both the rotor and stator. This results in three distinct, high intensity work zones at each rotor / stator location.

1. The mixture passes through the first set of rotor slots or teeth

2. then through the first ring of slots on the stator

3. and through the second ring of slots in both the rotor and stator

Shearmill/Shearpump Models with 3 shear heads provide 6 mixing stages with 9 work zones to handle your toughest processing needs.