![]()

Starmet CMI: Proven technologies with a respect for the environment.

Through focused innovation we have developed cost effective technologies and processes to help the clean-up legacy materials from government and commercial energy facilities.Converting radioactive scrap materials to useable shielding products and uranium hexafluoride into its soluble elements, are two ways that Starmet is dedicated to implementing novel reclamation processes to otherwise unwanted scrap materials.

Starmet CMI is the

only fully integrated depleted uranium processing facility in

North America!

|

|

Latest Breakthroughs:UF6 Conversion

Starmet operates the only production facility in North America capable of converting uranium hexafluoride (UF6) to uranium tetrafluoride (UF4). UF6 is a low level radioactive by product of the enrichment of uranium. From UF4

we produce three very useful products, uranium oxide aggregate, depleted uranium metal to support our uranium products and high value fluorine products such as silicon tetrafluoride (SiF4). Our ability to convert UF6 is already having an impact in helping to "clean-up" the stockpiles of UF6 at commercial and government energy facilities.

DUCRETE™ Shielding

Uranium oxide aggregate (uranium 1 inch pellets) when mixed with concrete, becomes a new enhanced radiation shielding material, DUCRETE™ Shielding. This patented material now offers engineers a low cost and highly effective ( 2 1/2 - 3 times as dense as concrete) solution for the shielding and storage of highly radioactive waste products.

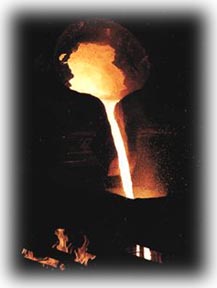

Recycling Technology

Processing equipment once used to produce nuclear energy and materials is becoming idled throughout the United States. In an effort to minimize waste and conserve resources in dealing with these stockpiles, Starmet is currently remelting and recycling radioactively contaminated steel. This "beneficial reuse" approach allows the productive use of millions of pounds of radioactive metal which would otherwise be buried. Our metal melting technology is an environmentally sound process for remelting the contaminated steel to be reprocessed into useful storage containers or shielding products.

Contact Starmet CMI to learn how our Advanced Recycling Technologies can help you!