|

|

|

business > plasma systems and contact angle analysis equipment > plasma systems

|

| System Specifications |

- Main: 115 VAC, 15amp

- RF Power: 300W, 13.56 MHz

- RF Match: Automatch

- Control: Windows based PC control

- Physical Size: 24" W x 24" L x 12" H, weight

75 lbs

- Chamber: 8" diameter, 10" depth; capacitively coupled; one gas feed

- Gas Feed: One MFC included

- Options: Vacuum Pump; oxygen service on pump; mist filter on

pump; capacitance manometer; throttle valve; 23 cfm pump (requires

3P 208 VAC); pump filtration system, 2nd MFC

- Chamber Options: Quartz, Pryex, Aluminum

|

|

(Click

to see 3D Model) |

|

|

| The two models are configured differently in reactor chambers and vacuum units to accommodate parts in different size and volume. PC control, advanced gas input, mixing, high-power vacuum and shelf configurations provide these systems the ability to handle various requirements in precision cleaning and surface modification. |

|

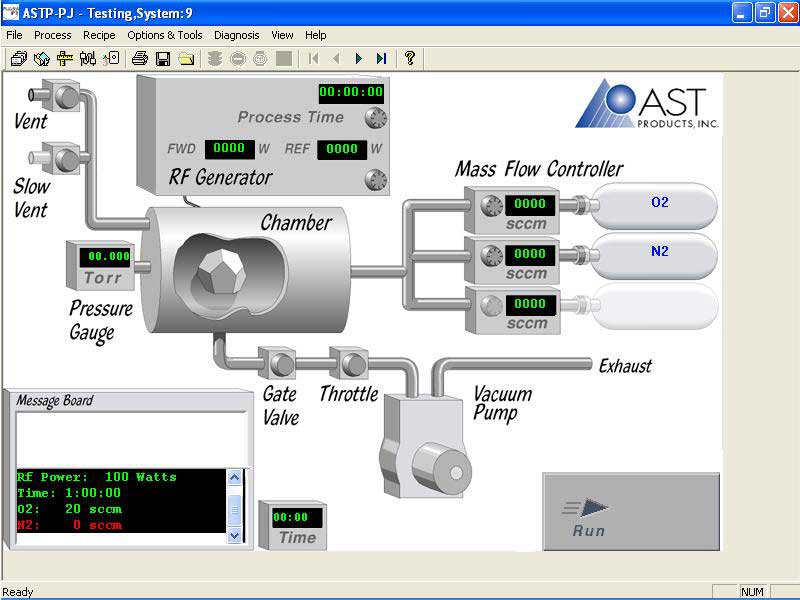

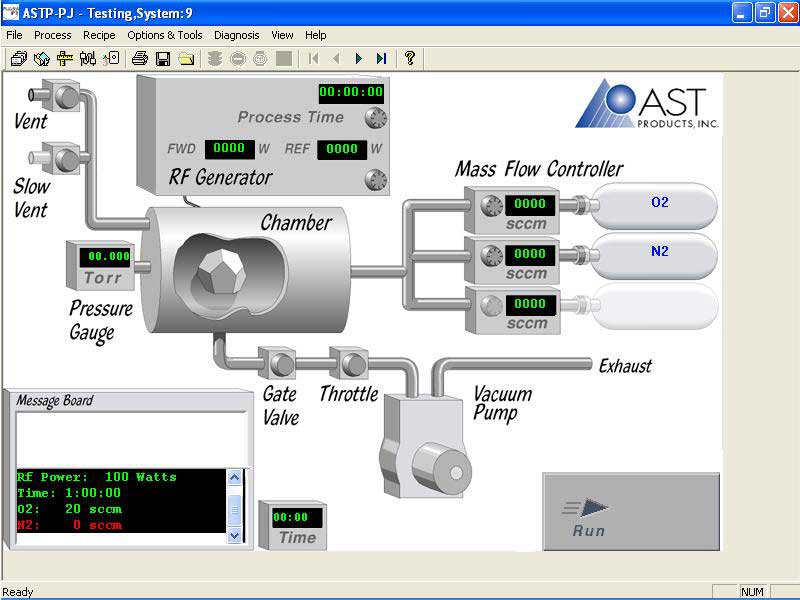

| System Configuration |

| REACTOR CHAMBER |

- All-aluminum construction

- PS350 work volume: 16.75" H x 13.5" W x 20" D

- PS500 work volume: 21" H x 14.5" W x 27" D

- Primary plasma driven shelf design

- Patented power distribution (US Patent no. 4,887,005 / 5,190,703 / 5,228, 963 / 5,468 560 / 5,733,511)

- Dielectric isolation of electrodes preventing RF interaction with chamber walls

- Front-to-back laminar distributed gas flow

- 4 glass shelves (9 slots

total)

|

| PROCESS CONTROL SYSTEM |

- Microprocessor controller stores an infinite number of

process recipes

- Digital displays for: PROCESS TIME, PRESSURE, GAS FLOW and RF POWER

- Automatic self-diagnostics touch screen display

- Automatic error checking of gas flow pressure, RF, forward and reflected power

- 2 gas lines with individual mass flow controllers and isolation valves

(3rd MFC optional)

- Fast and slow vent controls

|

| RF GENERATOR |

- 0 - 600 watt, 13.56 MHz, solid-state generator

- Automatic impedance matching network with fast automatic tuning

- RF automatic impedance matching network

- Temperature probe (option)

- N2 backfill (option)

|

| PUMP PACKAGES |

- Turnkey installation (including flexible plumbing and all fittings.)

- 50 cfm 2-stage rotary vane pump (or alternative high-capacity 180 cfm roots blower package) with integral connection to process controller

- Pump option for lubricating with inert oil

- External filtration system with pressure gauge (option)

- Oil-mist separator (option)

- Integral pump starter with control panel (on blower packages)

|

|

|

|