| VascuLAST™ coatings are |

|

| Versatile |

|

| VascuLAST™ can be the host matrix for a variety of anti-restenosis compounds. Bioactive compounds that act by inhibiting angiogenesis, inflammation, smooth muscle cell proliferation, or the clotting cascade can be incorporated. |

|

| Uniform |

|

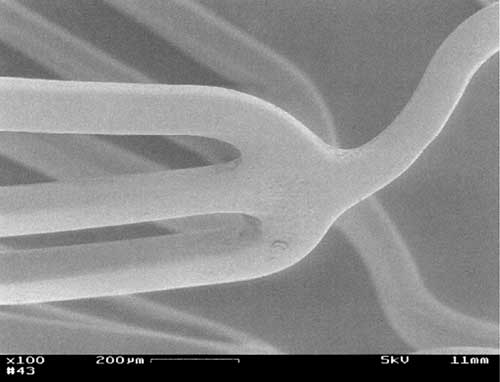

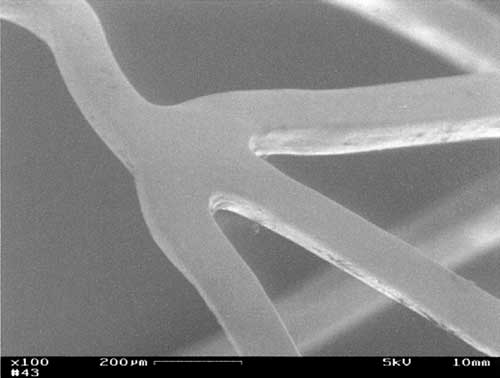

| VascuLAST™ is applied by a process that is easily scaled up and can be adapted to any stent design. The coating is uniform and does not bridge over any part of the stent. |

|

| Customized |

|

| VascuLAST™ has been shown to be effective in the reduction of restenosis with certain stent designs and bioactive compounds. It can be customized to include compounds prescribed by a device manufacturer or can be used as part of a coating offered by a pharmaceutical manufacturer. AST works with customers closely through the development process to ensure that the coating meets the design requirements of any kind of customer. |

|

| Flexible and tenacious |

|

| VascuLAST™ coatings strongly adhere to substrates even when the devices are fully expanded with no flaking or delamination. |

|

| Controllable |

|

| VascuLAST™ coatings can be enhanced with a patented AST treatment that controls and prolongs the release of agents into surrounding tissue. |

|

|

|

|

|

| How does VascuLAST™ work? |

|

|

|

| Another new coating in the BioLAST family, VascuLAST™ is a surface treatment used to prevent the re-narrowing of vessels after medical intervention. While this usually happens during angioplasty procedures, it may also occur elsewhere. AST-sponsored animal trials have demonstrated the successful use of VascuLAST™ to incorporate anti-restenosis agents into implantable devices. |

|